Publisher:Administrator Date in:2019-01-25

Guide: according to the list of top ten automobile groups in 2018 released by focus2move, Volkswagen Group once again won the title with a total sales volume of 10.83 million vehicles, with a year-on-year growth of 2.2%. The second largest Toyota group sold 10.52 million vehicles, up 2.2% year on year

Recently, in the list of top ten automobile groups in 2018 released by focus2move, Volkswagen Group once again won the championship with a total sales volume of 10.83 million vehicles, with a year-on-year growth of 2.2%. Compared with the total sales volume of 10.52 million vehicles (2.2% year-on-year growth) of the second Toyota group, the sales volume of the Volkswagen Group in 2018 was better than that of the Toyota group!

VW vs Toyota, wolfburg factory tends to be intelligent factory standard

As one of the world's top automobile manufacturers, the brand influence of Volkswagen and Toyota need not be said. In fact, behind the number one and number two sales in the world is the competition between the two automobile manufacturing factories. Among them, the Volkswagen headquarters automobile factory not only realizes mechanization, automation and intelligence to a large extent, but also has the basic characteristics of intelligent factories, and is a model benchmark for global automobile manufacturing enterprises.

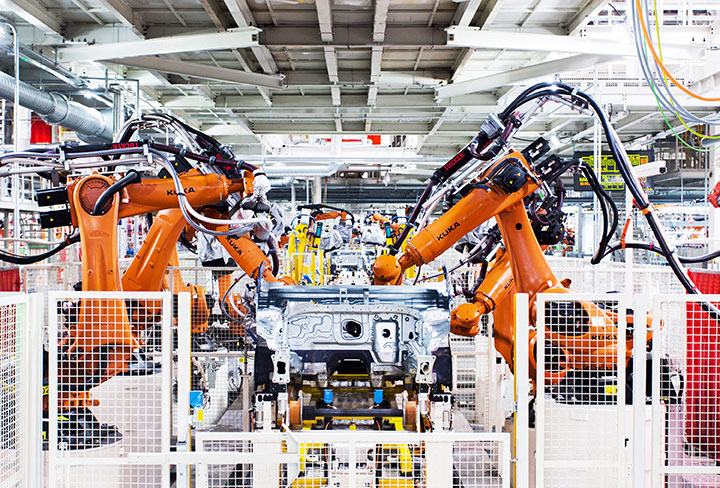

Volkswagen wolfburg factory

The Wolfsburg factory, the headquarters of Volkswagen Group, is located in Wolfsburg, Germany. It has the first "ghost workshop" that introduces robots, unmanned three-dimensional warehouse, flexible production line, etc. At the same time, with the strong digital support, wolfburg factory can let more than 10000 parts from all over the world be transported into the factory by train every day, and at the same time, it can realize the amazing operation of zero inventory. Among them, "ghost workshop", as the earliest layout of VW Wolf fort factory automation, is a powerful guarantee of factory automation. In the workshop, famous robot brands such as KUKA and Fanuc can be seen everywhere. At present, the seven axis robot of human-computer interaction has been introduced into the subpackage process of Volkswagen Wolf fort factory, and the proportion of human-computer interaction robot will be gradually increased in the future. It is understood that 90% of the processes in Wolf fort factory have been automated with the help of a large number of robots. For example, taking the welding process as an example, the body of a car involves more than 600 welding parts, and the Volkswagen Wolf fort factory can complete it in only four and a half hours. Digital flexible production is also one of the remarkable characteristics of Wolf fort factory. In the case of mass production of more than 3500 vehicles per day and daily supply of vehicles that need to be sold in more than more than 200 countries around the world, Wolfsburg factory can still meet different needs to complete personalized products according to real-time monitoring data. Relying on the good background of German intelligent manufacturing, Volkswagen wolfburg factory has the inherent manufacturing technology advantage, which is also the most powerful guarantee for the quality of Volkswagen Group cars.

Toyota group Yuanting factory

Toyota group assembly plant is located in Yuanting factory, Japan. It mainly produces crown and other high-grade cars, with an annual output of about 50000 sets and a production beat of 2 minutes and 30 seconds. Compared with the auto factory with an annual output of hundreds of thousands of cars, Yuanting factory is not large, and compared with Volkswagen wolfburg, its automation level is not too high, which mainly reflects Toyota's lean production mode TPS (Toyota Production system). TPS of Toyota Yuanting factory is mainly reflected in four aspects: first, JIT automation. JIT does not emphasize a high level of automation, but the production of the necessary number of products within the necessary time. Toyota adopts the pull operation method, emphasizes the sequence, determines the production rhythm according to the sales progress, formulates the operation quantity and standard operation, and produces according to the demand, mainly emphasizes the good combination of people and equipment. Second, good production site management. TPS strictly controls the waste generated in the production process, including the waste of excess production, the waste of waiting, the waste of handling, the waste of over processing, the waste of inventory, the waste of action, the waste of unqualified products, etc. Third, strictly control the quality in each process. Each process of Toyota Yuanting factory has a light alarm or automatic alarm function to ensure that the quality problems of each process will not flow into the next process. Finally, we will continue to improve all existing management methods. TPS will continuously improve production management as the market changes, so that products can better serve the target customers. In general, the development of Toyota Yuanting factory has accumulated profound and unique Toyota genes and Toyota characteristics, which is also the main reason for the unique quality of Toyota vehicles. It can be seen from the comparison that as the headquarters manufacturing plant of the company, Volkswagen wolf Castle factory and Toyota Yuanting factory are quite different. The former is characterized by large-scale automation, while the latter has developed into a production mode with its own characteristics. And it is such differentiation that both enterprises occupy their own market "world" in the global market.

Unlike Toyota, Volkswagen is more interested in the Chinese market

In addition to the differences in headquarters manufacturing plants, VW and Toyota hold different "attitudes" to China, a huge automobile consumer market. It is understood that Volkswagen Group expanded its factories in Qingdao, Tianjin and Foshan in 2018 to support the group's electrification strategy "roadmap e" and SUV offensive. Among them, FAW Volkswagen Foshan factory is the second factory that tends to be the standard of intelligent factory after wolfburg factory. As of May 31, 2018, Foshan factory has completed 109566 sets, with a total of 1178796 finished vehicles. It is expected that by 2020, Foshan factory will have 2 production lines and 10 models. At that time, the whole Foshan base will have the maximum production capacity of 600000 vehicles and 770000 vehicles. Foshan factory has become the guarantee of automobile production capacity in the mass China market. The expansion of Volkswagen's three major factories can be said to meet the needs of the Chinese market, so as to provide more comprehensive services to the users of the Chinese automobile market. In terms of global market layout, Toyota group mainly relies on Toyota and Lexus, and its other brands mainly serve Japan. Moreover, its market positioning is too small, such as Subaru. For the Chinese market, Toyota's "action" does not seem obvious. Conclusion: with the continuous improvement of material living conditions, people's demand for cars continues to increase. Volkswagen Group and Toyota group, as the global automobile manufacturing giants, are the brands that the global automobile consumers focus on. In the past 2018, both VW and Toyota have made great achievements, but VW has once again led Toyota with excellent sales performance, which is closely related to VW's manufacturing link and market layout. But in fact, as the leader in the automobile manufacturing industry, Volkswagen and Toyota are in the leading position in the world in terms of manufacturing technology, and are worth learning from global automobile manufacturers!